MDF vs. Particle Board What’s the difference? Global Hardware Ltd. Blog

This MDF vs. particle board type include: LDF - low density fiberboard; HDF - high density fiberboard; Each board goes through the same process, but the difference between MDF and particle board is that each board uses a different amount of material. As you use more material to make a board, its density will also increase.

Particle Board Vs MDF What Is MDF What Is MDF Used For CivilDetail

What is the difference between MDF and Particle Board? When choosing your furniture, regardless of whether it is ready-made or will be made to order, you must know from the beginning if it is made of chipboard or MDF, because each material has its advantages and disadvantages.

Particle Board vs MDF Which is Better?

Particle board, also known as chipboard, is made from wood particles bonded with resin. It's affordable but less durable and prone to moisture damage. MDF, or medium-density fiberboard, is made from wood fibers and resin. It's smoother and more uniform than particle board, but also susceptible to moisture.

Particle Board Vs. Medium Density Fiberboard (MDF) Which one should you choose? Homebliss

Both particle board and MDF have pros and cons when checking their environmental-friendliness. They are made from wood scraps. They undergo a recycling method that devotes to saving trees. It shows friendliness to the ecosystem. However, the disadvantage is that dust and formaldehyde are essential concerns when using composite materials.

MDF Desks vs. Particle Board Desks Which is Better in 2023?

MDF vs Particle Board - Uses, Properties, Advantages and Disadvantages Subjects Estimation & Costing Building Materials ⮞ Aggregate ⮞ Brick ⮞ Cement ⮞ Concrete ⮞ Mortar ⮞ Sand ⮞ Steel Building Construction Geotechnical ⮞ Foundation ⮞ Geology ⮞ Soil Mechanics ⮞ Site Investigation Environmental Eng. Structural Eng. ⮞ Structural Design Earthquake Eng.

PLYWOOD VS. MDF VS. PARTICLE BOARD? Dean

MDF board (Medium-density fiberboard) and particle board are both pressed wood products that can be used to make shelving, furniture, cabinets, and more. But they have their share of differences. So which is best for your needs?

Plywood vs MDF vs Particle Board ! Which one is Best and Durable YouTube

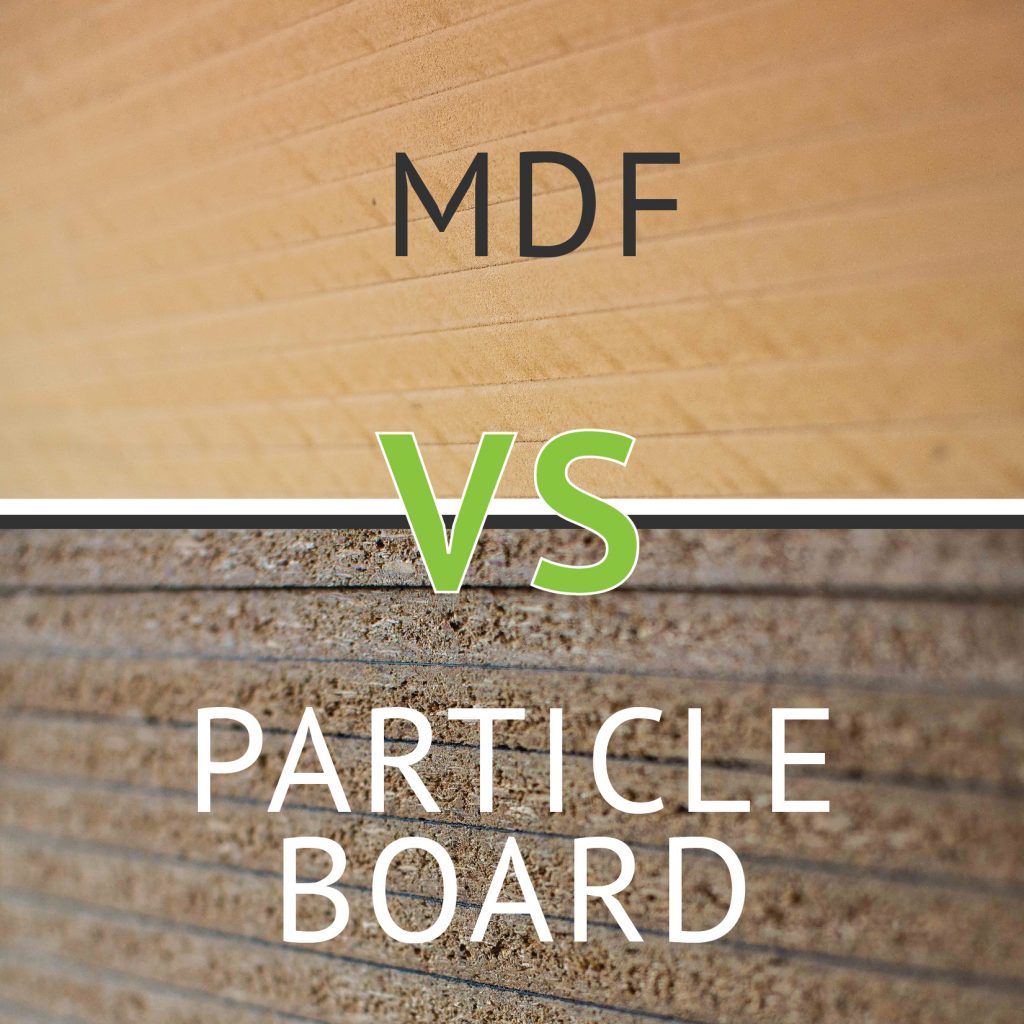

Particle board and MDF are pressed-wood products engineered from wood fibers mixed with synthetic resin adhesives. The main differences are the size and types of wood fibers used during its manufacture. MDF uses fine, granular particles for a more homogenous density with smooth, tight edges for strength and workability.

mdf vs particle board, particle board vs mdf, mdf comparison, particle board versus mdf

Medium density fiberboard, or MDF, and particle board are both pressed wood products often used for cabinets, shelving, furniture and paneling. The two materials share similarities in terms of price, density, strength and durability. MDF, made from fine wood fiber, is primarily used in cabinetry, shelving, furniture and molding.

MDF vs Particle Board Which is Cheaper or Better? Decor Pursuits

MDF Vs Particle-board: What is the Difference? What is MDF? MDF, the long-form term - medium-density fibreboard, is a type of engineered wood made using wood fibre. The wood fibres are stuck together using glue and then put into a hot machine that compresses the fibres to form a board. It is a great home décor material that is inexpensive.

What’s the Difference Between MDF & Particle Board?

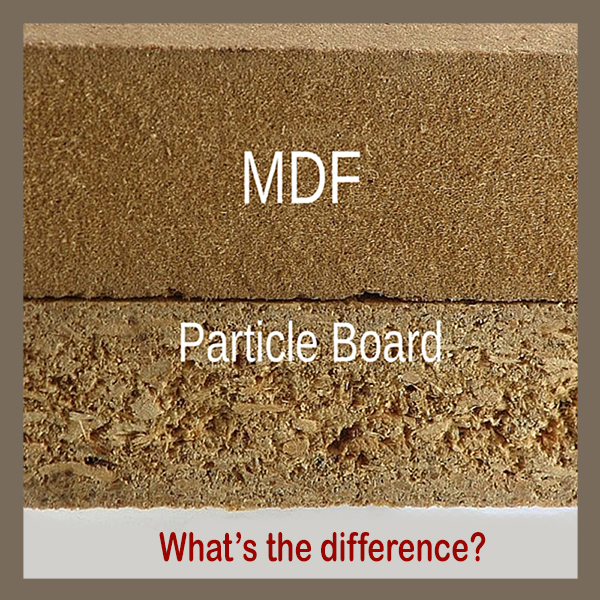

You can tell the difference in composition between medium-density fiberboard (MDF) and particle board by looking at the roughness or smoothness of the board. For instance, MDF has a smooth finish as it is made of very small wood fibers, almost like flour that is of the same size.

Difference Between MDF and Particle Board YouTube

The particle board vs MDF debate isn't a very lively one, there are professionals and DIY enthusiasts alike that have somewhat differing opinions. This doesn't mean that the particle board vs MDF debate is pointless but simply implies that because different people would have used materials of varying quality for different applications and.

MDF Vs Particle Board What is the Difference? HomeLane Blog

What are their types, uses, and significances? How to choose them and when? I will tell you about fiber and particle boards, the differences between HDF, MDF, and Particle Board materials, and their uses, advantages, disadvantages, types with sizes to help you select the right one for your next project. What Are Fiberboard and Particle Board?

Particle Board vs. MDF Gator Millworks, Denham Springs, LA

MDF weighs much more when compared to particle boards. Particle boards are lightweight. Cost MDF plywood price ranges from Rs. 40-80/sq. ft. depending on interior or exterior grade. *These prices are subject to change depending on the market value Particle board price ranges from Rs. 15-50/sq. ft. *These prices are subject to change depending.

MDF vs. Particle Board Which Engineered Board Suits Your Project?

Benefits of Particle Board in Cabinetry. Particle Board vs MDF offers several benefits that make it a popular choice, particularly for low-budget furniture and cabinetry. Firstly, particle board is cost-effective and provides a low-cost alternative to solid wood or plywood, making it an affordable choice for those on a budget.

Comparing Furniture Materials Particle Board, MDF & Plywood Vidifurniture

by Karen Nakamura Cheap, plain and definitely not wood. That's how many woodworkers describe particleboard and MDF (medium-density fiberboard), but think these words instead: inexpensive, uniform and stable. Inexpensive. MDF and particleboard panels run $25 to $35 a sheet (oversized at 49 in. by 97 in. so you can cut off a dinged edge). Uniform.

MDF vs. Plywood Differences, Pros and Cons, and When To Use What

MDF stands for medium-density fiberboard, which is an engineered wood composite made up of wood fibers. Because the MDF is composed of small wood fibers, there is no visible wood grain, rings, or knots. The making of the composite uses the fibers, glue, and heat to create a tight bonding board. Both softwood and hardwood are used to manufacture.