Proper wire joint and soldering 3 way YouTube

Learn How to Solder Correctly. In this video I show you the tools, tips, tricks, and techniques to properly solder, from what type of solder and flux you should use to how to splice the.

Soldering Tutorial Inline Splicing 7 Steps (with Pictures) Instructables

11 min How to Solder - A Beginners' Guide to Soldering Learn how to solder safely with our guide, sharing tips on soldering techniques for a variety of scenarios. Topics Covered in this Guide What is Soldering?

TGP » Which Type of Soldering Iron to Use for Guitar Electronics

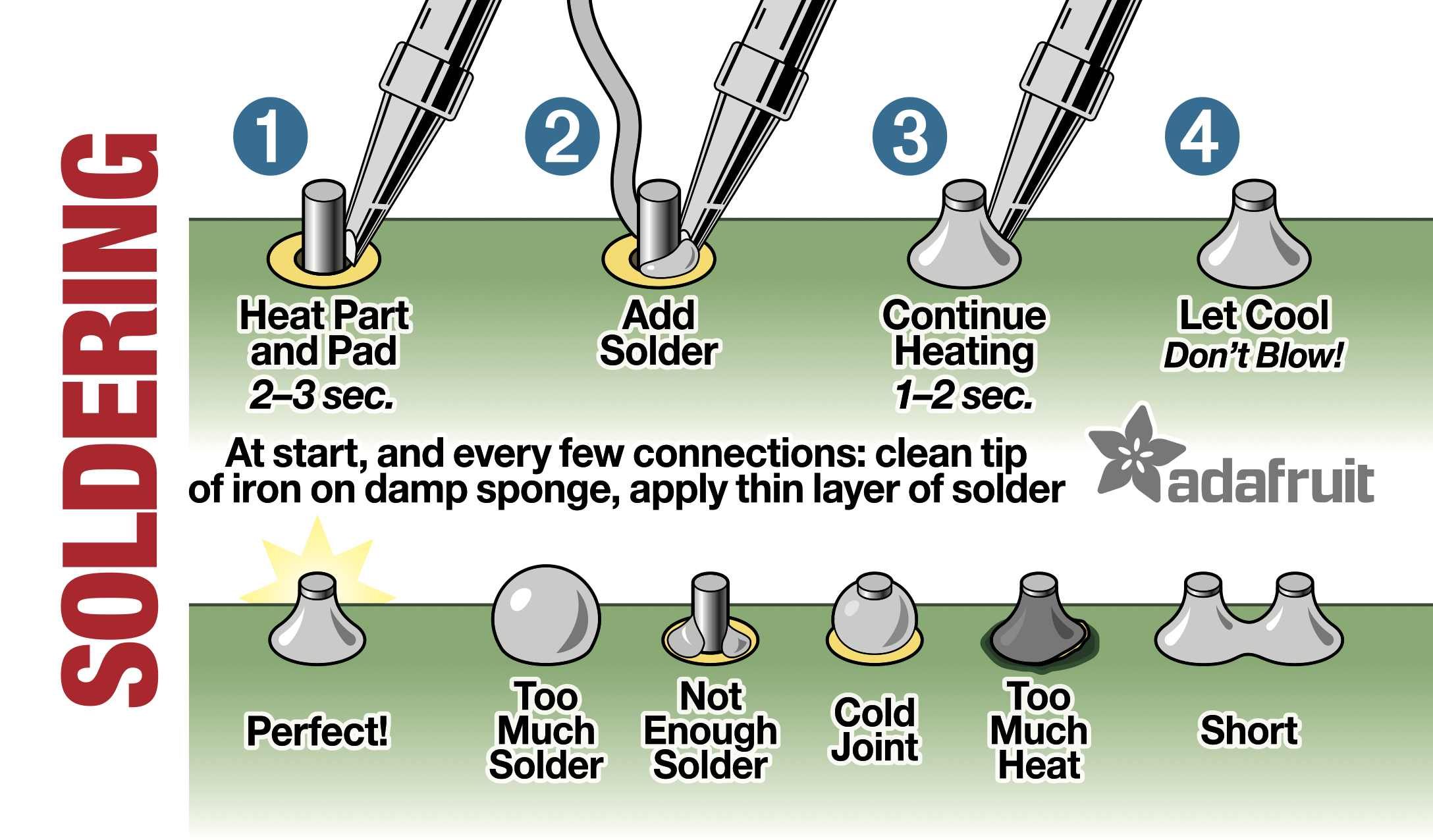

Soldering, the process of connecting different types of metals by melting solder, is a crucial skill for working on avionics, printed circuit boards, and other types of electronics. While soldering may seem like a daunting task at first, it becomes second nature after some practice!

How do I test my soldering on the Pi Zero? Raspberry Pi Forums

soldering. It takes some practice to make the perfect joint, but, like riding a bicycle, once learned is never forgotten! The idea is simple: to join electrical parts together to form an electrical connection, using a molten mixture of lead and tin (solder*) with a soldering iron.

Basic Soldering Guide How to Solder Electronic Components

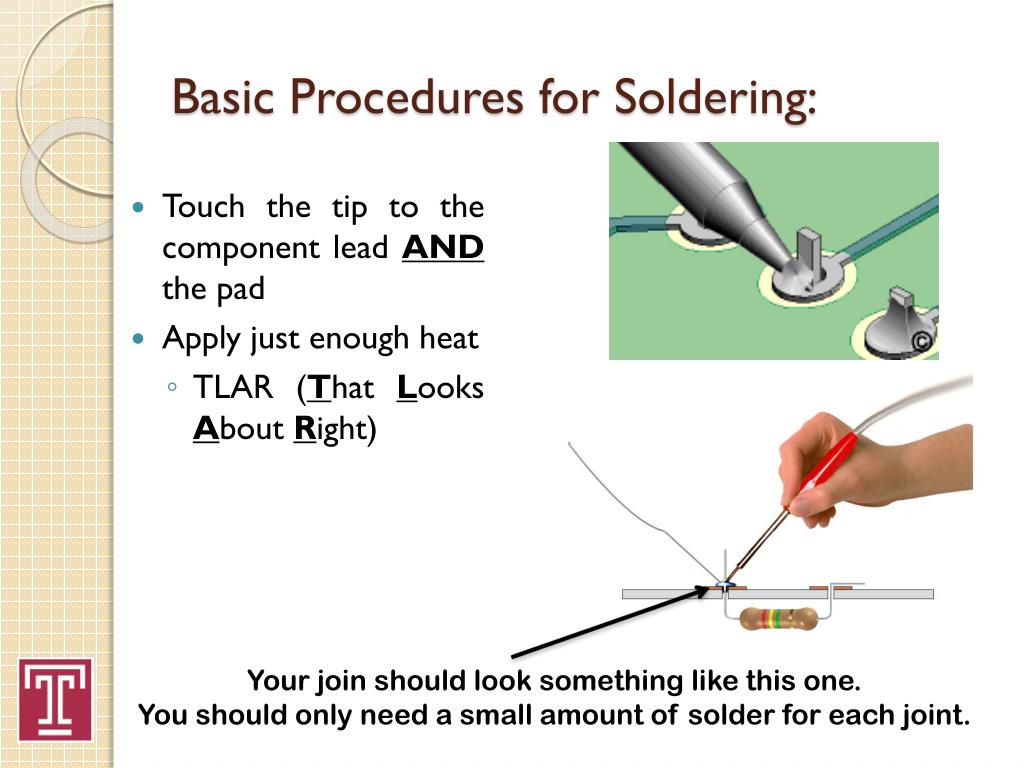

Use a wire brush or sandpaper to gently scrub the surface, ensuring a clean and shiny finish. Once the connectors are clean, apply a small amount of flux to the tip of the soldering iron. This will help the solder flow smoothly and evenly. Touch the tip of the iron to the connector and apply a small amount of solder.

How to Solder Wires Together (Best tips and tricks) Solder Wire, Soldering Iron, Soldering Tools

Step 5: Cleaning Up. Just like before when you started clean your tip either with your sponge or your wire cleaner. Sponge: Get sponge wet and rub your tip on both sides to remove any solder and or dirt. Wire Cleaner: Stick your soldering tip in the cleaning wire a few times until clean.

Soldering Wires to Wires Soldering Basics Soldering for Beginners YouTube

The maximum soldering temperature should be at least 5-10°C lower than the melting temperature of any thermoplastic components (if used). Time: The devices must be held at the peak soldering temperature long enough to ensure the proper wetting of the solder connections.

Learn how to solder w/ proper soldering techniques. We outline the basics of soldering irons

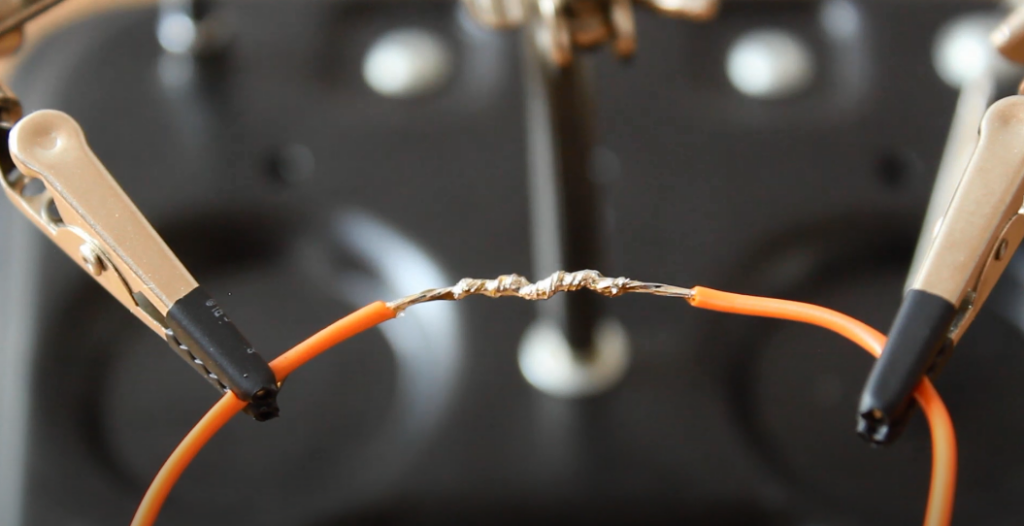

Apply the solder to the surface and allow a thin coating to form on the surface. Allow the surface to cool. When tinning stranded insulated wires, strip the wire to the appropriate length for the joint being made. Tin the wire, using only enough solder to make the stripped wire solid.

PPT Introduction to Soldering PowerPoint Presentation, free download ID2529475

How To Solder Wires Join wires together and more with soldering tips for beginners By Lee Wallender Updated on 03/22/23 Reviewed by Larry Campbell The Spruce / Kevin Norris In This Article Before You Begin Instructions Soldering to Electrical Components FAQ Project Overview Working Time: 5 mins Total Time: 20 mins Skill Level: Beginner

How to Solder Wires to Each Other and Circuit Boards? Solderingironguide

4. Bring the heat to the joint you want to solder. Apply the tip of the soldering iron to the joint you want to solder, and leave it in place. A couple of seconds is usually enough, but for bigger.

Learn to Solder Part 3 Soldering Wires Together. YouTube

184 24 Featured Soldering is an essential skill for hobbyists and anyone interested in DIY electronics projects. This article will provide step-by-step instructions for inline splicing, a widely used procedure in electronic assemblies. Inline splicing involves joining two stranded wires in a straight line.

Knew nothing about cables or soldering, made my first one within 4 hours of getting my kit. r

Many of our videos are comedic & satirical & not intended to cultivate antisocial or unlawful behavior. Thank you for supporting our Channel through the belo.

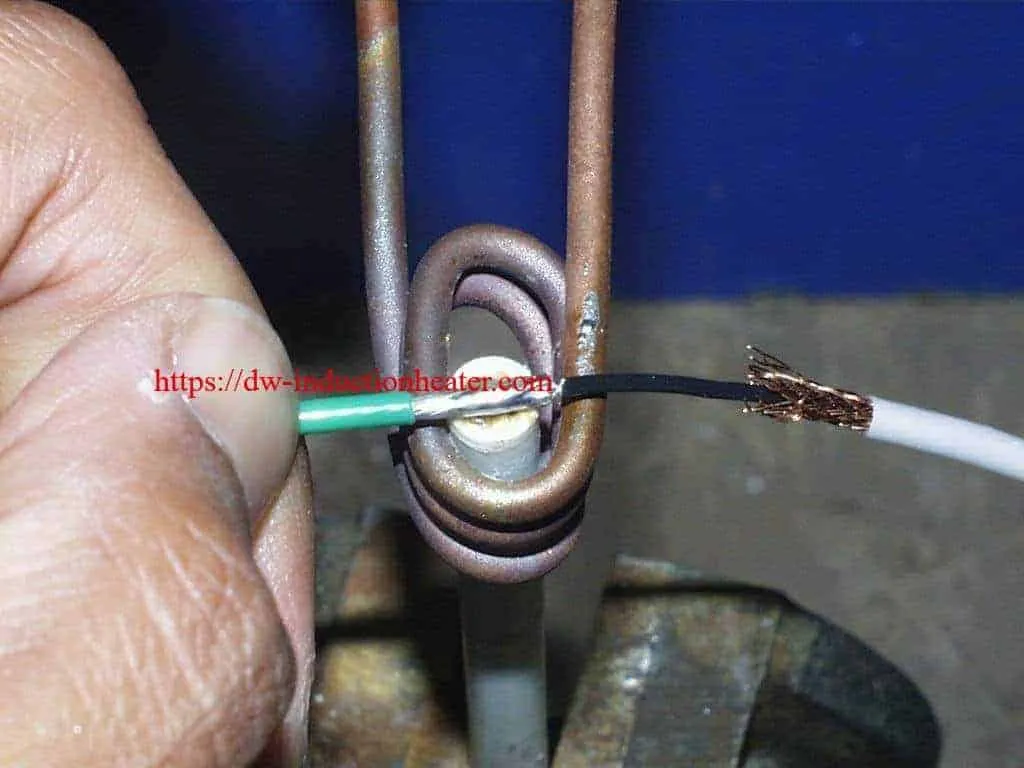

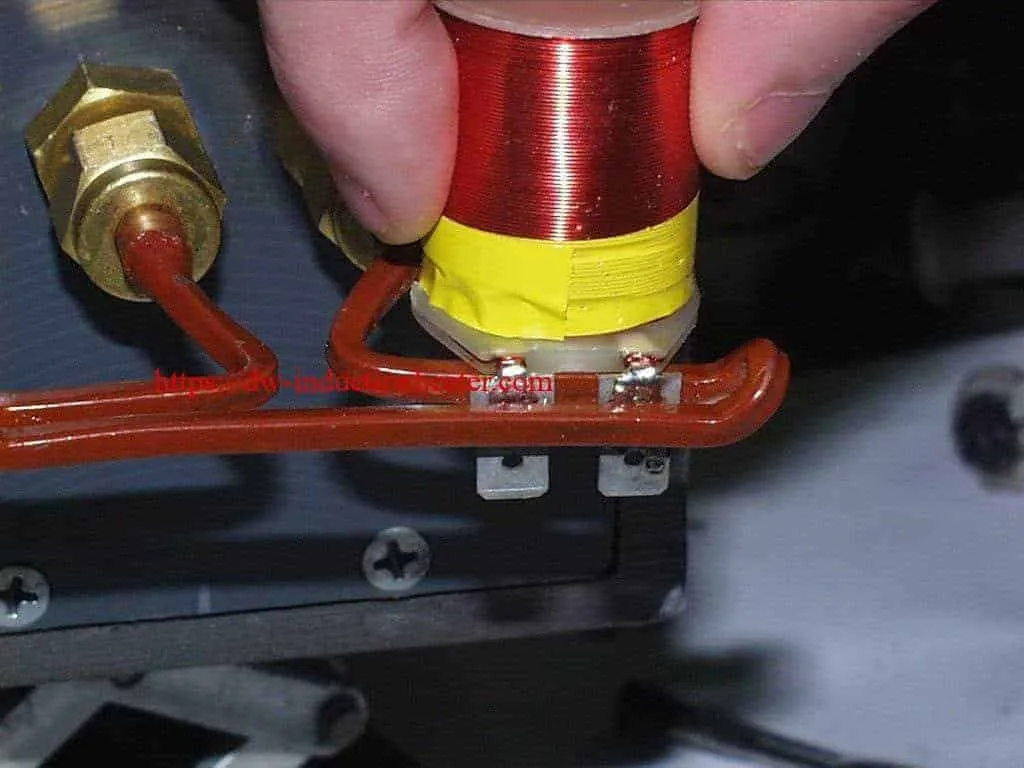

Induction Soldering Wire of Coaxial HLQ Induction Heating Machine Manufacturer

What Is Soldering? If you were to take apart any electronic device that contains a circuit board, you'll see the components are attached using soldering techniques. Soldering is the process of joining two or more electronic parts together by melting solder around the connection.

Induction Soldering Wires Onto Connection

The Bright Pixel 6.33K subscribers Subscribe 4.1K 199K views 8 years ago Links to products used in the description below. Learn how to make your own cables like the pros. This is an extended, in.

Soldering Multiple Wires for a Distribution Joint 4 Steps (with Pictures) Instructables

1. Soldering Iron: A high-quality soldering iron with adjustable temperature control is crucial for coax cable soldering. This allows you to set the right temperature to avoid damaging the cable or connectors. 2. Solder: Use a lead-free solder with a diameter suitable for the size of the cable.

Is soldering extra wires to increase current capacity on a pcb trace good design? Electrical

Soldering Process. Once you have all the necessary components in place, it's time to begin soldering your stainless steel cable. First, make sure that the surfaces of both cables are clean and free of any debris or dirt. Next, apply flux paste to the area where the two cables will be joined together. This will help create a stronger bond.